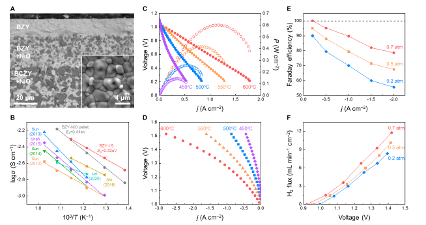

With the material system operating at lower temperatures, protonic ceramic electrochemical cells (PCECs) can offer high energy efficiency and reliable performance for both power generation and hydrogen production, making them a promising technology for reversible energy cycling. However, PCEC faces technical challenges, particularly regarding electrode activity and durability under high current density operations. To address these challenges, we present a scalable nano-architecture ultra-porous oxygen electrode with triple conductivity, designed to enhance catalytic activity and interfacial stability through a self-assembly approach. Electrochemical cells incorporating this advanced electrode have demonstrated robust performance, achieving a peak power density of 1.50 W cm⁻2 at 600 °C in fuel cell mode and a current density of 5.04 A cm-2 at 1.60 V in electrolysis mode, with enhanced stability on transient operations and thermal cycles. The underlying mechanisms are closely related to the improved surface activity and mass transfer due to the dual features of the electrode structure. Additionally, the enhanced interfacial bonding between the oxygen electrode and electrolyte contributes to increased durability and thermomechanical integrity. This study underscores the critical importance of optimizing electrode microstructure to achieve a balance between surface activity and durability.

https://www.nature.com/articles/s41467-025-59477-9